In oil and gas projects, steel pipe is frequently grouped together in conversation, but OCTG (Oil Country Tubular Goods) and line pipe actually fulfill distinct roles. They are designed to meet different performance requirements and are associated with various operational and safety considerations.

As a distributor and supply chain management services company, we often encounter this topic early in project planning. Recognizing the distinction between OCTG and line pipe is more than a technical detail; it has direct implications for well integrity, regulatory compliance, cost management, and schedule reliability.

This article provides a high-level breakdown of the differences, offering practical insights for engineers and project managers responsible for specifying, sourcing, and executing oil and gas projects.

The Core Difference: Function, Not Just Specification

The most important distinction between OCTG and line pipe is how and where they are used.

OCTG: Structural Integrity of the Well

OCTG includes casing, tubing, and drill pipe, each of which plays a role in constructing and maintaining the well itself.

Key characteristics:

- Installed vertically or directionally

- Designed to withstand collapse, burst, and tensile loads

- Critical to well integrity and safety

Typical applications:

- Casing to stabilize the wellbore

- Tubing to produce hydrocarbons to the surface

- Drill pipe for drilling operations

OCTG is about structure and control, keeping the well stable, isolated, and safe throughout its life cycle.

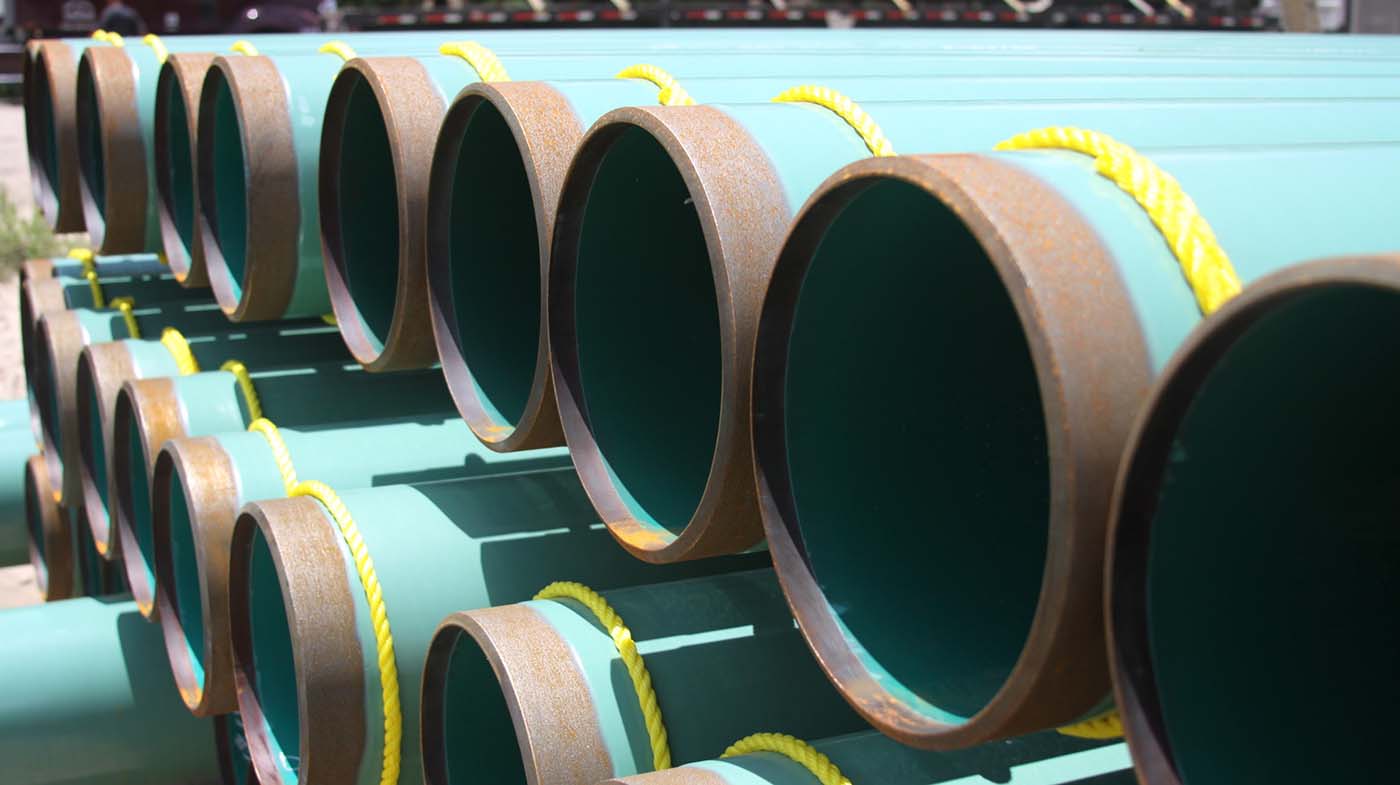

Line Pipe: Transporting Hydrocarbons

Line pipe is used to transport oil, gas, and other fluids from one point to another, whether that’s from a wellhead to a processing facility, between facilities, or to a transmission system.

Key characteristics:

- Designed for continuous flow

- Installed horizontally or near horizontal

- Subject to internal pressure, environmental exposure, and corrosion

Typical applications:

- Gathering lines

- Flowlines

- Transmission pipelines

- Offshore export lines in the Gulf of Mexico

Line pipe is about movement—moving product safely, efficiently, and in compliance with environmental and regulatory standards.

API Compliance and Safety Considerations

Both product categories are API-approved, but they are approved under different standards for different reasons:

- API 5L (Line Pipe): Focuses on pressure containment, weld quality, toughness, and long-term transport reliability.

- API 5CT (OCTG): Focuses on mechanical performance under extreme downhole conditions, including collapse resistance and tensile strength.

From a project management standpoint, ensuring the correct API standard is specified and sourced is essential for:

- Meeting operator and regulatory requirements

- Passing inspections

- Protecting people, assets, and the environment

The Supply Chain Reality: Why Early Planning Matters

From our experience managing pipe supply across North America and the Gulf of Mexico, the biggest challenges are rarely technical; they’re logistical.

These include:

- Long mill lead times for certain sizes or grades

- Limited availability during market upcycles

- Coordination across pipe, valves, fittings, and flanges

- Aligning delivery schedules with drilling or construction windows

Because we supply both OCTG and line pipe products and maintain relationships with all major API-approved mills, we help customers:

- Forecast material needs accurately

- Secure mill slots early

- Optimize procurement across multiple product categories

- Reduce risk of delays caused by material shortages

Our buying power and supply chain visibility allow us to manage these complexities so project teams can stay focused on execution.

Final Takeaway

The difference between OCTG and line pipe is not subtle and it’s not optional.

- Line pipe moves hydrocarbons

- OCTG builds and protects the well

- Each has a distinct role, specification, and risk profile

- Getting it right requires both technical understanding and supply chain expertise

When specified, sourced, and managed correctly, both product types work together to support safe, compliant, and efficient oil and gas operations.

Need Help Sourcing OCTG or Line Pipe?

Whether you’re planning an onshore project in North America or an offshore development in the Gulf of Mexico, we provide:

- Technical product guidance

- Mill coordination and forecasting

- End-to-end supply chain management

Contact our sales team to discuss your upcoming requirements and ensure you have the right materials, at the right time, from the right mills.